Navigating the Future with Chevron Conveyor Belts: Unleashing the Potential of Industrial Conveying Systems

Image Source: Google

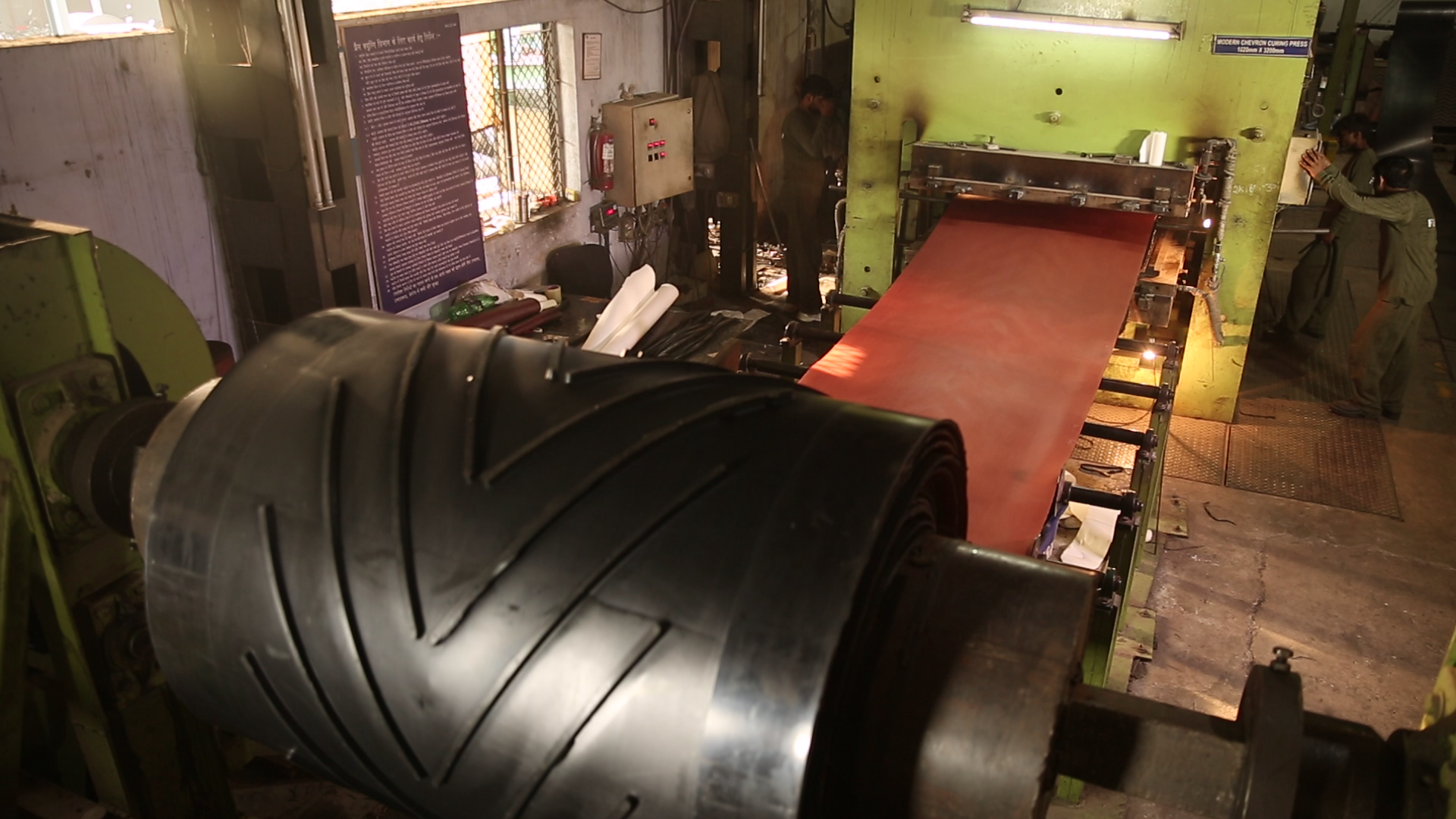

Industrial conveying systems play a crucial role in the efficiency and productivity of various industries. Chevron conveyor belts are a key component of these systems, offering unique advantages in navigating the future of industrial conveying. With their special V-shaped profiles that are designed to carry materials at steeper angles and prevent slipping, Chevron conveyor belts are ideal for transporting bulk materials such as coal, aggregates, and grains in industries ranging from mining to agriculture.

One of the main benefits of Chevron conveyor belts is their ability to handle materials on inclines and declines with ease. The V-shaped pattern on the belt surface provides a higher coefficient of friction, which prevents materials from sliding back down the conveyor. This is particularly useful in applications where materials need to be transported over steep angles or across long distances.

In addition to their superior grip and traction, Chevron conveyor belts are also known for their durability and longevity. Made from high-quality materials such as rubber and fabric, these belts are designed to withstand the harsh conditions of industrial environments, including extreme temperatures, heavy loads, and abrasive materials. This level of durability ensures minimal downtime and maintenance costs, allowing businesses to focus on their core operations without worrying about conveyor belt failures or replacements.

As industries continue to evolve and adopt new technologies, Chevron conveyor belts are also being integrated with advanced features to enhance their performance and efficiency. For example, some Chevron conveyor belts are equipped with sensors and monitoring systems that allow real-time tracking of belt conditions and material movement. This data can be used to optimize conveyor belt operations, prevent potential issues, and improve overall efficiency.